biw sheet metal Requirements of BIW structure: • Comfortable space • Strength & stiffness • Low weight material • Corrosion resistant • Aerodynamic & good appealing structure: BIW joinery defines the exterior . 3M Unitek Gemini Twin Brackets Cuspid Hook Mbt - 0.022: Rounded-Shape Corners for improved patient comfort. The corners and ligating mechanism feature the same buccal curvature as the bracket body.

0 · sheet metal biw design

1 · how to stamp biw sheets

2 · how to design biw parts

3 · biw welding joint design

4 · biw structural design

5 · biw sheet metal design tips

6 · biw sheet metal design questions

7 · biw parts diagram pdf

The item ID for Metal Sheet is 68. This is the spawn command to give yourself Metal Sheet in Unturned. Copy the command below and paste it into your Unturned game or server admin console to obtain. You can also customize the command by entering the values below.

sheet metal biw design

Well, I already redesigned a couple sheet metal parts, not only for BIW architecture, and removed plenty of features from the previous design, delivering a clean and cheaper design BUT keeping the same system .Body in white (BIW) is the stage in automobile manufacturing in which a car body's frame has been joined together, that is before painting and before the motor, chassis sub-assemblies, or trim (glass, door locks/handles, seats, upholstery, electronics, etc.) have been integrated into the structure. Assembly involves different techniques such as welding (spot, MIG/MAG, or friction stir), rivetingThe document provides an introduction to body-in-white (BIW) design, outlining the different types of BIW structures like unibody, space frame, and frame-mounted designs. It also describes the major systems that make up the BIW .

Requirements of BIW structure: • Comfortable space • Strength & stiffness • Low weight material • Corrosion resistant • Aerodynamic & good appealing structure: BIW joinery defines the exterior . Basically, all open windows or slots at structures that we may need hand access during systems installation, we need to avoid direct contacts of sheet metal edges to hands and arms of operators.

sheet metal box diy

Body-in-white (BiW) is the name given to a car body’s sheet when all its components—barring moving parts (e.g., hoods, fenders, etc.), trims (e.g., glass, seats, etc.), or chassis .The term “Body in White” (BIW) refers to the stage in automotive manufacturing where the car body’s sheet metal components are assembled before the addition of moving parts and other components. During this stage, techniques such as .

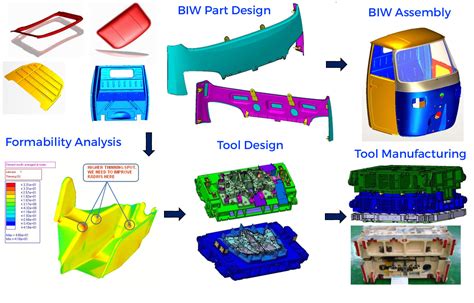

The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization.this paper design and analyze of BIW component by using Auto form Simulation software and design die and punch forming surfaces for defect free part using CATIA V5 is discussed. Well, I already redesigned a couple sheet metal parts, not only for BIW architecture, and removed plenty of features from the previous design, delivering a clean and cheaper design BUT keeping the same system performance.

Body in white (BIW) is the stage in automobile manufacturing in which a car body's frame has been joined together, that is before painting and before the motor, chassis sub-assemblies, or trim (glass, door locks/handles, seats, upholstery, electronics, . Some stamped metal part design best practices often help to achieve expected body-in-white (BIW) structures performance and prevent potential problems.The document provides an introduction to body-in-white (BIW) design, outlining the different types of BIW structures like unibody, space frame, and frame-mounted designs. It also describes the major systems that make up the BIW like the front end, underbody, side body, and closures.Requirements of BIW structure: • Comfortable space • Strength & stiffness • Low weight material • Corrosion resistant • Aerodynamic & good appealing structure: BIW joinery defines the exterior and interior look. • Sufficient space for packaging and .

Basically, all open windows or slots at structures that we may need hand access during systems installation, we need to avoid direct contacts of sheet metal edges to hands and arms of operators.

Body-in-white (BiW) is the name given to a car body’s sheet when all its components—barring moving parts (e.g., hoods, fenders, etc.), trims (e.g., glass, seats, etc.), or chassis subassemblies—have been welded together.The term “Body in White” (BIW) refers to the stage in automotive manufacturing where the car body’s sheet metal components are assembled before the addition of moving parts and other components. During this stage, techniques such as welding, riveting, or bolting are used to join the body panels together.The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization.this paper design and analyze of BIW component by using Auto form Simulation software and design die and punch forming surfaces for defect free part using CATIA V5 is discussed.

Well, I already redesigned a couple sheet metal parts, not only for BIW architecture, and removed plenty of features from the previous design, delivering a clean and cheaper design BUT keeping the same system performance.Body in white (BIW) is the stage in automobile manufacturing in which a car body's frame has been joined together, that is before painting and before the motor, chassis sub-assemblies, or trim (glass, door locks/handles, seats, upholstery, electronics, . Some stamped metal part design best practices often help to achieve expected body-in-white (BIW) structures performance and prevent potential problems.

The document provides an introduction to body-in-white (BIW) design, outlining the different types of BIW structures like unibody, space frame, and frame-mounted designs. It also describes the major systems that make up the BIW like the front end, underbody, side body, and closures.Requirements of BIW structure: • Comfortable space • Strength & stiffness • Low weight material • Corrosion resistant • Aerodynamic & good appealing structure: BIW joinery defines the exterior and interior look. • Sufficient space for packaging and .

how to stamp biw sheets

how to design biw parts

Basically, all open windows or slots at structures that we may need hand access during systems installation, we need to avoid direct contacts of sheet metal edges to hands and arms of operators.

Body-in-white (BiW) is the name given to a car body’s sheet when all its components—barring moving parts (e.g., hoods, fenders, etc.), trims (e.g., glass, seats, etc.), or chassis subassemblies—have been welded together.The term “Body in White” (BIW) refers to the stage in automotive manufacturing where the car body’s sheet metal components are assembled before the addition of moving parts and other components. During this stage, techniques such as welding, riveting, or bolting are used to join the body panels together.The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization.

sheet metal brake instructions

6X6X4 SC Junction Box Type 1 Screw Cover Enclosure, Low Carbon Steel, Gray, Powder Coated, 4 In Overall Width, 6 In Overall Length, 6 In Overall Height, 4 Knockouts, 3 LB Slang .

biw sheet metal|how to design biw parts